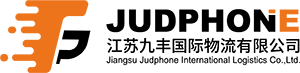

Reposted from “Digital Dharma Circle”: One Article to Understand: The Relationship Between ERP and CRM, MRP, PLM, APS, MES, QMS, WMS, SRM.

These days, whether it’s manufacturing, trading companies, or project-based businesses, whenever the topic of digitalization and informatization comes up, the scene is often like this:

◦ Boss: “Should we implement an ERP?”

◦ Operations Head: “Don’t we also need a CRM now?”

◦ Production Head: “What about MES? Not having one seems unadvanced.”

◦ IT: “Actually, APS, PLM, QMS, WMS, SRM… they are all quite important.”

Then the meeting room falls silent for 3 seconds.

No one dares to make the call because no one can clearly explain: What exactly is the relationship between these systems? Is one more advanced than the other? Does having more mean you’re more capable?

In today’s article, I won’t take sides with vendors or consulting firms. I’ll just stand from the perspective of actual business operations and clarify these systems:

● What they do

● What problems they solve

● Their relationship with ERP

● When to implement them and when not to

Remember just one sentence:

ERP is not the opposite of all other systems; it is the central nervous system.

1. First, let’s clarify the most confusing point:

ERP ( Enterprise Resource Planning) is not a specific function; it is a set of operational foundations.

Many people think of ERP and their first reaction is: financial system, inventory management, invoicing and bookkeeping… This is only 30% correct. A truly mature ERP is essentially about three things:

1.Unifying data standards

2.Integrating business processes

3.Embedding operational rules

In other words:

ERP manages how the enterprise operates, not how a specific department works.

So, the systems you hear about later—CRM, MRP, PLM, APS, MES, QMS, WMS, SRM—none of them replace ERP. They are either sub-capabilities of ERP or extensions of ERP.

Let’s break them down one by one.

II. ERP and CRM: One Manages How Money is Made, the Other Manages How Customers are Secured

What does CRM ( Customer Relationship Management) do?

Simply put, CRM does one thing: transforms sales from a gut-feeling process into something manageable, reviewable, and replicable.

It focuses on:

• Where customers come from (leads)

• Who is following up (salesperson)

• What stage the follow-up is at

• Whether there is a risk of losing the deal

• Whether upselling is possible after closing

So what does ERP manage?

ERP cares about:

• Whether this order can be accepted

• What the cost is

• Whether gross profit can be calculated clearly

• Whether shipment, invoicing, and payment collection form a closed loop

You can understand it this way: CRM manages the frontline charge, ERP manages the backend support.

Deals are won in CRM, and fulfilled, settled, and accounted for in ERP.

Without ERP, even with many deals in CRM, finance, inventory, and delivery will be a mess. Without CRM, even with a complete ERP, front-end sales rely entirely on manual tracking and feeling.

In a nutshell: For sales-driven enterprises, it must be CRM + ERP working together, not choosing one over the other.

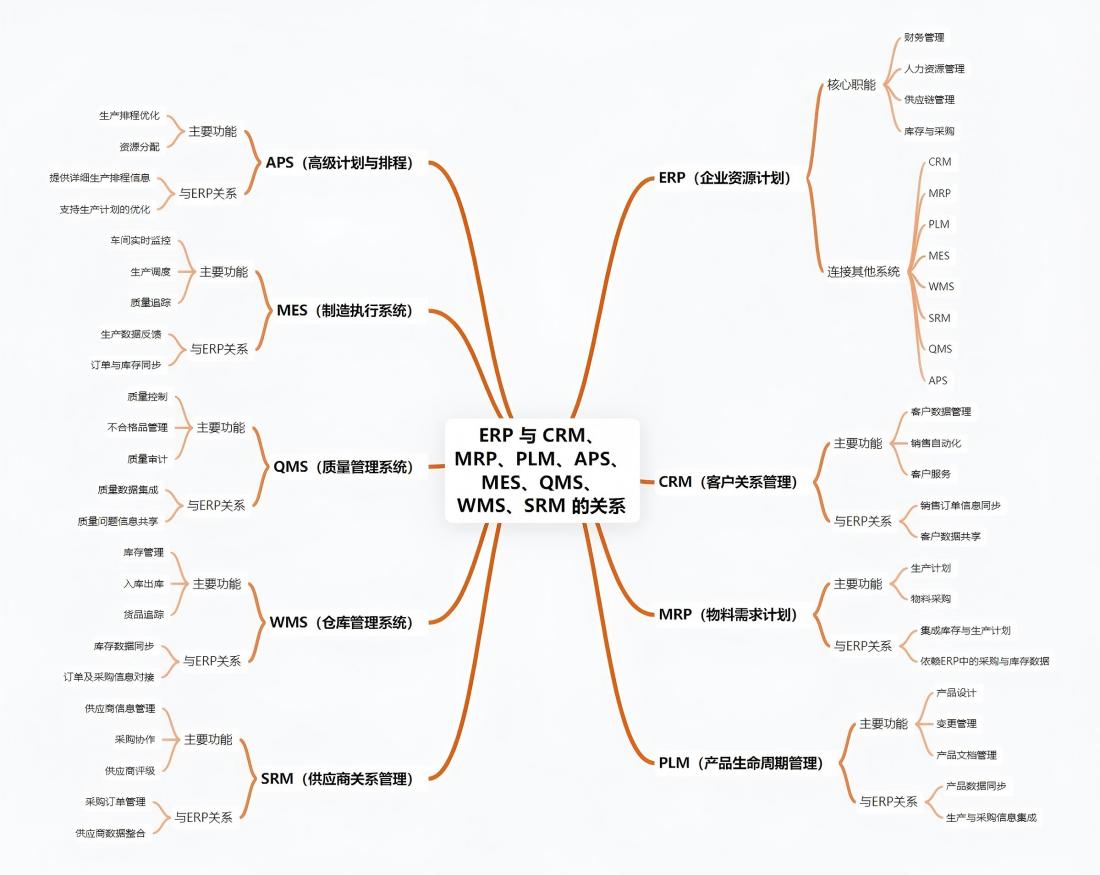

III. ERP and MRP: MRP is Not an Independent System, but a Capability

This is the most misunderstood one.

What exactly is MRP?

MRP = Material Requirements Planning. Its core logic is just one sentence:

Based on orders and inventory, calculate what to buy, how much to buy, and when to buy it.

Note, I said calculate.

What’s its relationship with ERP?

In modern ERP: MRP is basically one of the core modules of ERP. In other words: without the foundational data from ERP (BOM, inventory, orders), MRP calculations cannot be accurate.

If you buy a standalone MRP system, it’s likely that:

• Data needs to be imported manually

• Results need manual judgment

• You still rely on gut feeling after the calculation

Many enterprises’ problem is not the lack of MRP, but:

• Inaccurate BOM

• Inaccurate inventory

• Chaotic order changes

Then they blame the system for being. If MRP calculations are inaccurate, 90% of the time it’s a basic data problem, not an algorithm problem.

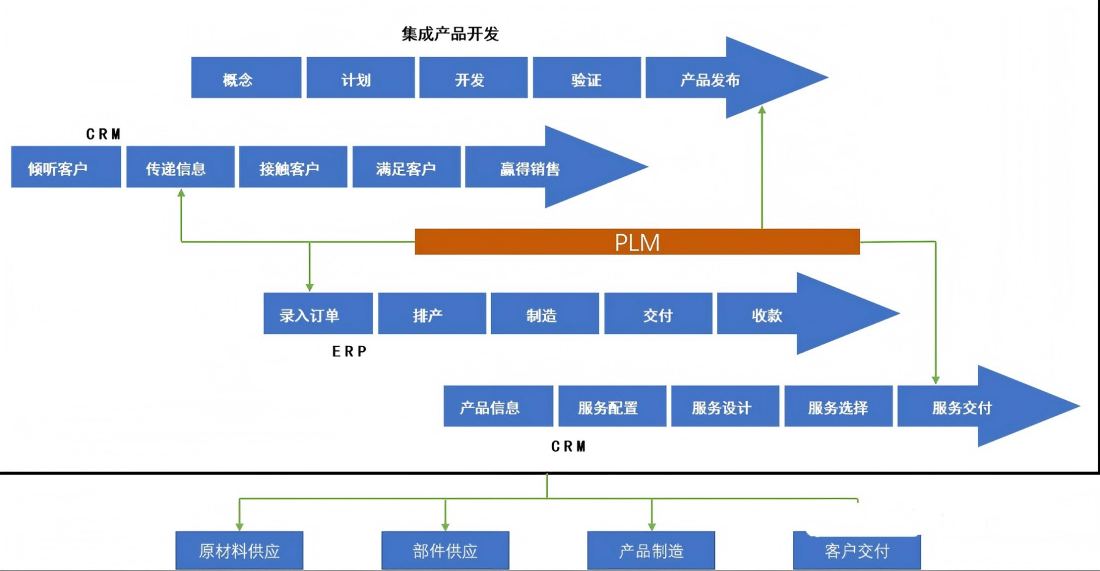

IV. ERP and PLM: One Manages How to Sell, the Other Manages How to Design

What does PLM do?

PLM = Product Lifecycle Management. It focuses on:

• Product structure (BOM)

• Drawings, process documents

• Version changes

• Technical standards

In a nutshell, PLM manages the product from design to finalization.

When does ERP need PLM?

If you are in non-standard manufacturing, have multi-version products, or frequent design changes, then the BOM management built into ERP is probably insufficient.

At this point, you need PLM to manage technical data upfront, and ERP to handle production, procurement, and cost in the backend, i.e.:

• PLM decides what to use in the design

• ERP decides what to actually buy, use, and how much to spend

If the two systems are not integrated, the most likely problem is: the drawing is V3, procurement buys according to V2, cost is calculated based on V1, and then the whole company shoulders the blame together.

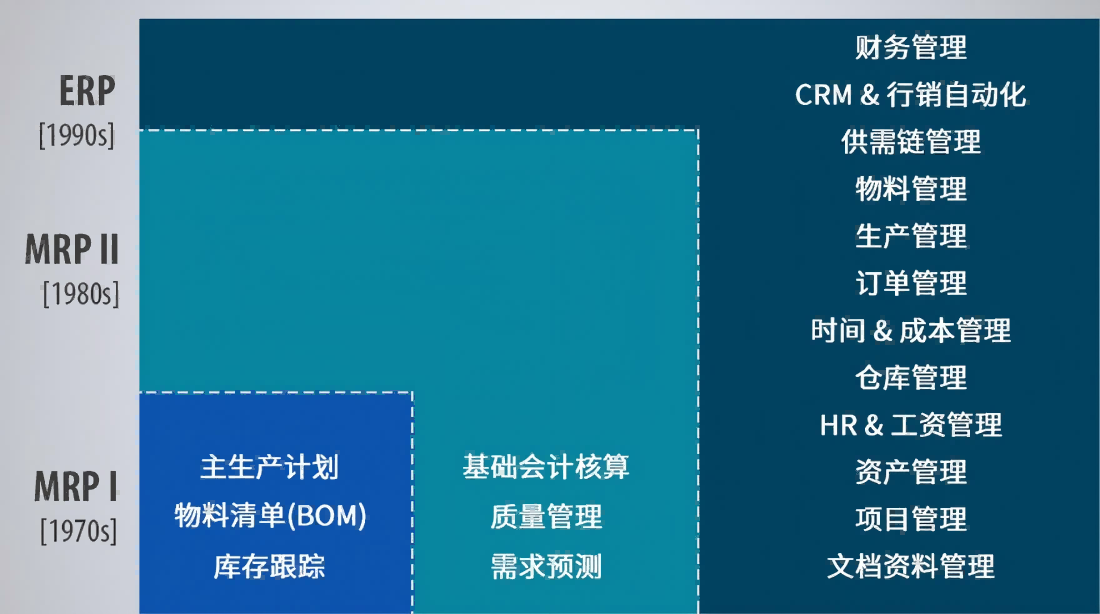

V. ERP and APS: One Calculates Whether It Should Be Done, the Other Calculates How to Schedule It Most Reasonably

What does APS do?

APS = Advanced Planning and Scheduling. It solves a very specific and painful scenario: too many orders, limited resources, tight deadlines, and manual scheduling can’t keep up.

APS focuses on equipment capacity, process sequence, changeover costs, and delivery priority.

Can’t ERP handle production scheduling?

It can, but ERP leans more towards rough planning, while APS leans more towards detailed scheduling.

You can understand it as:

• ERP tells you: How much to produce this month

• APS tells you: Which order this specific machine should work on first tomorrow morning

When should you implement APS?

Not necessarily when you reach a certain scale, but when you meet these characteristics:

• High variety, low volume

• Frequent delivery date changes

• Obvious equipment bottlenecks

Otherwise, even with APS implemented, you’ll likely have beautiful Gantt charts while the shop floor still doesn’t follow them.

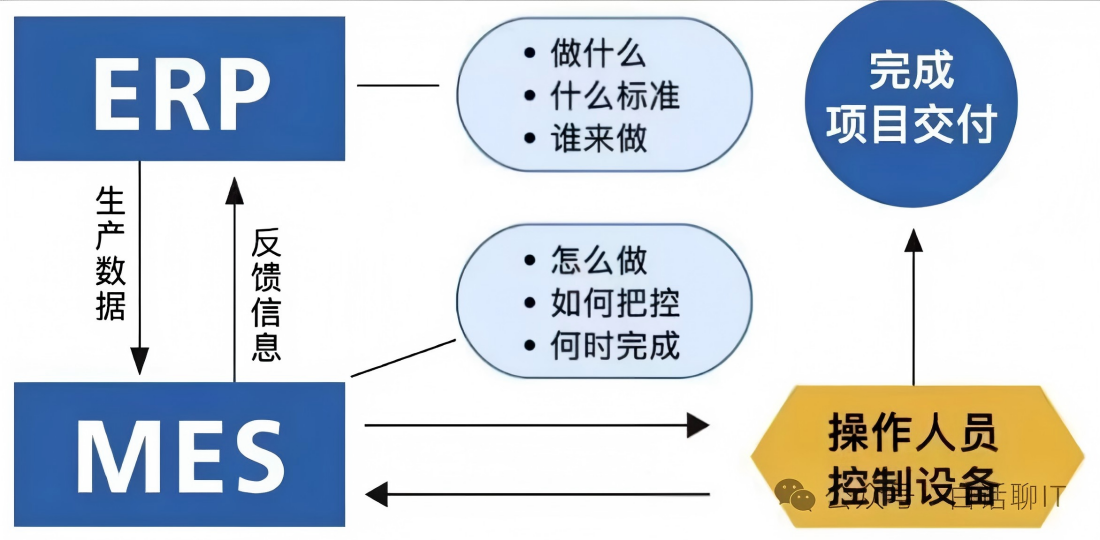

VI. ERP and MES: One is in the Office, the Other is on the Shop Floor

What does MES manage?

MES = Manufacturing Execution System. It monitors:

• Work order execution

• Process reporting

• Equipment status

• Production exceptions

In a nutshell, MES manages what actually happens on the shop floor.

What does ERP manage?

ERP manages plans, costs, materials, and settlement.

The problem for many enterprises is that ERP plans are beautiful, but shop floor execution relies entirely on WeChat groups and whiteboards. In the end, the data in ERP is all entered after the fact.

The correct approach is:

• ERP issues plans

• MES provides real-time feedback on execution

• Cost, progress automatically flow back

Otherwise, ERP will forever be the “leadership-only” system.

VII. ERP and QMS: One Manages Results, the Other Manages Processes

What does QMS do?

QMS = Quality Management System. It monitors:

● Incoming inspection

● In-process inspection

● Outgoing inspection

● Non-conformities, corrective actions, preventive actions

Is the quality module in ERP enough?

For small businesses, yes. For industries with high-quality requirements, no.

Because the quality module in ERP is usually more about recording and results, while QMS emphasizes more:

● Process control

● Traceability

● Systematic improvement

QMS is responsible for how quality is managed, ERP is responsible for how quality results affect cost and delivery.

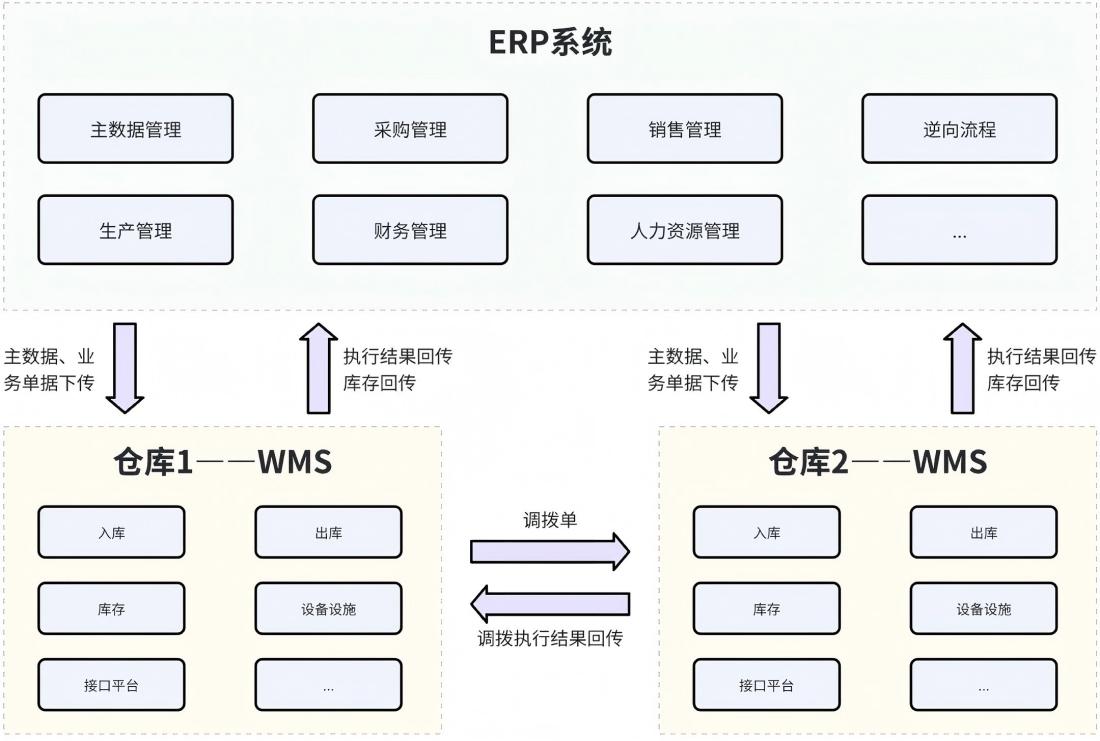

VIII. ERP and WMS: One Manages the Books, the Other Manages the Locations

What does WMS do?

WMS = Warehouse Management System. It solves:

● Location management

● Picking paths

● Batch numbers, expiration dates

● Barcodes, scanning

Doesn’t ERP also have inventory?

Yes, but ERP is more about quantity accounts and value accounts, while WMS manages:

● Where the goods are

● How to get them

● Who got it wrong

When do you need WMS?

When you encounter:

● Inventory counts are accurate, but locations are chaotic

● Finding goods relies on experience

● The cost of shipping the wrong goods is high

That’s the typical scenario for ERP + WMS.

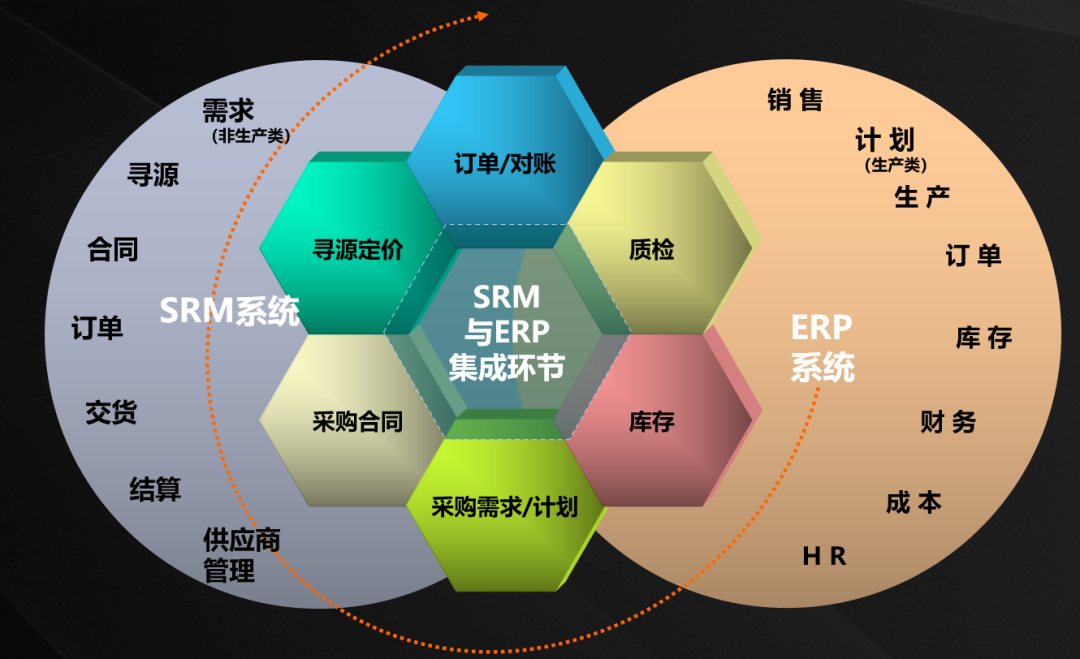

IX. ERP and SRM: One Manages Internal Processes, the Other Manages Supplier Collaboration

What does SRM do?

SRM = Supplier Relationship Management. It monitors:

● Supplier performance

● Delivery times, quality

● Reconciliation collaboration

● Procurement transparency

Isn’t the procurement module in ERP sufficient?

It is, but it only solves internal processes.

SRM solves cross-organizational collaboration problems, such as:

● Suppliers confirming orders online

● Online reconciliation

● Closed-loop handling of quality issues

X. Final Summary

You can directly remember this relationship diagram:

● ERP: Enterprise operational hub

● CRM: Sales front-end

● MRP: Material calculation capability

● PLM: Product and technology source

● APS: Advanced scheduling tool

● MES: Shop floor execution tool

● QMS: Quality system

● WMS: Warehouse execution

● SRM: Supply chain collaboration

It’s not that more systems are better.

Rather, is your current most painful point worth solving with a dedicated system?

——The End——

Post time: Jan-30-2026